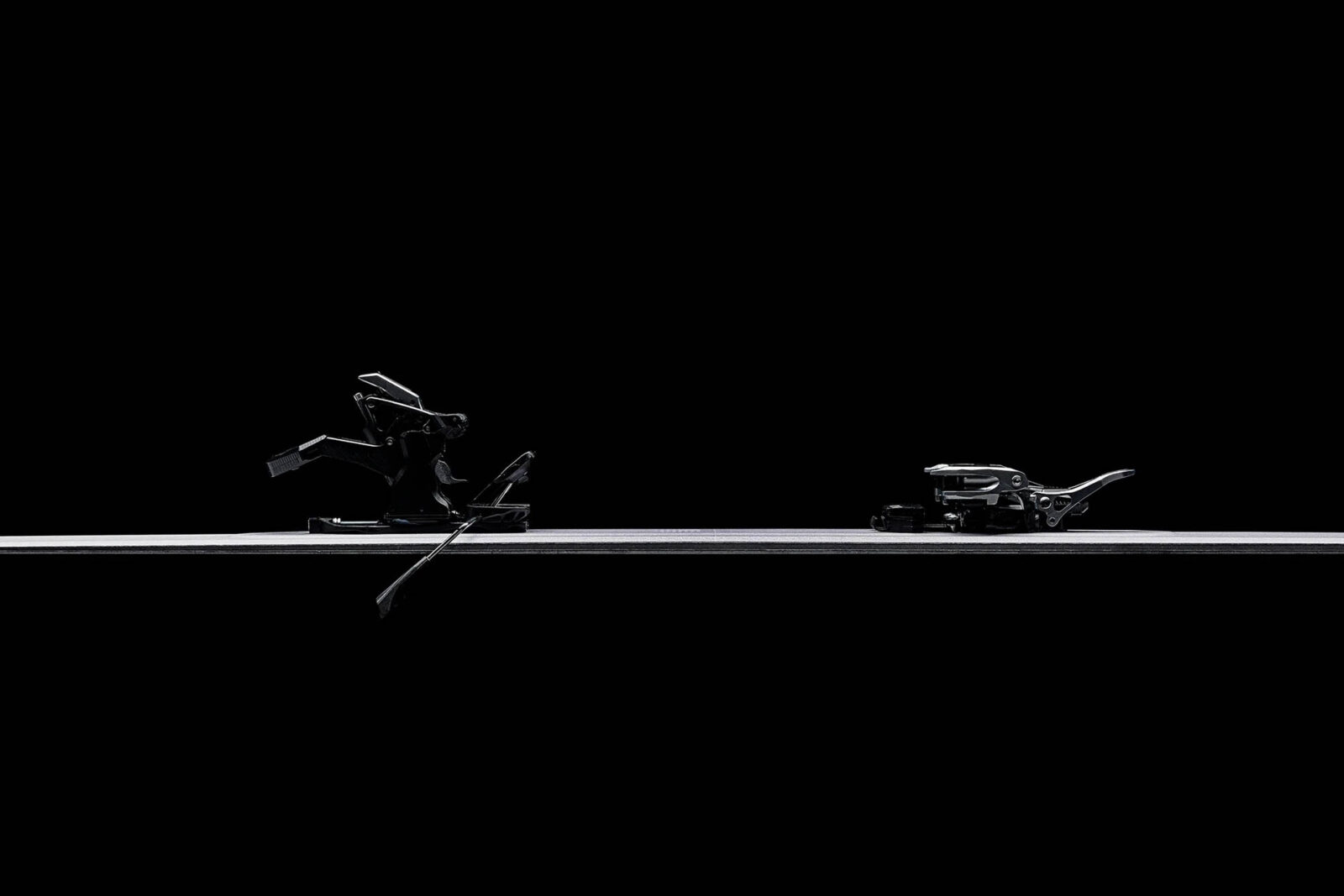

The Hy will be available in two versions, one with a release range of 4-11 and one with 6-13 (and both versions will be available in black or white variants). ATK calls it the “release range,” since it is not yet decided whether the Hy will be DIN certified, but the retention forces are at the levels of the respective DIN settings. While this range may sound a bit low at the upper end for some, it’s worth remembering that the Hy in downhill mode is a full alpine binding with a relevant displacement before final release of the boot—ATK specifies 7 mm of elastic travel for the heel piece and 18 mm on each side for the toe piece. That’s a big difference over a classic tech binding. As I already mentioned before, this displacement is relevant in dynamic skiing scenarios, and the energy absorption before a release depends on how the retention force increases in respect to the displacement. ATK showed some graphs on this matter that looked really good, and it suggests that the Hy will work well for most skiers in its available release range. It seems to work for their team rider Nikolai Schirmer, at least.

In terms of boot compatibility, the Hy works with most ski boots in downhill mode, whether they are classic alpine boots, modern freeride hybrid boots or traditional touring boots; for uphill mode you need a boot with pin inserts, of course. In order to fit different soles of a great variety of boot types, it is necessary to adjust the platform height of the toe piece in downhill mode. While many bindings deal with this adjustment via a screw mechanism, ATK opted for a solution with spacers. The reasoning behind it is that alpine boots have stiff and rather low profile soles that need a lot of rise. ATK uses rubber spacers in this case to add vibration absorption. For high-profile, rather soft touring soles, there are slim, hard plastic spacers for direct interaction. A feature of the Hy is that it can be used with different types of boots; it’s not likely, though, that customers will change their boots all the time—there is an adjustment range in heel piece positioning of 25 mm in case you do. Anyway, it is advised to check compatibility of a specific boot with the Hy before purchase, but a vast majority of available boots will work.